We enable AI for your traceability

Complete Traceability in Logistics and Production with AI-Powered Code Recognition

With our Vision AI Code Reader, you automate traceability in logistics and production - faster, more precise, and more efficient. Traceability is crucial today - in logistics and increasingly also in production at the individual part level. But manual processes, paper-based delivery notes, and incomplete master data make efficient processes difficult.

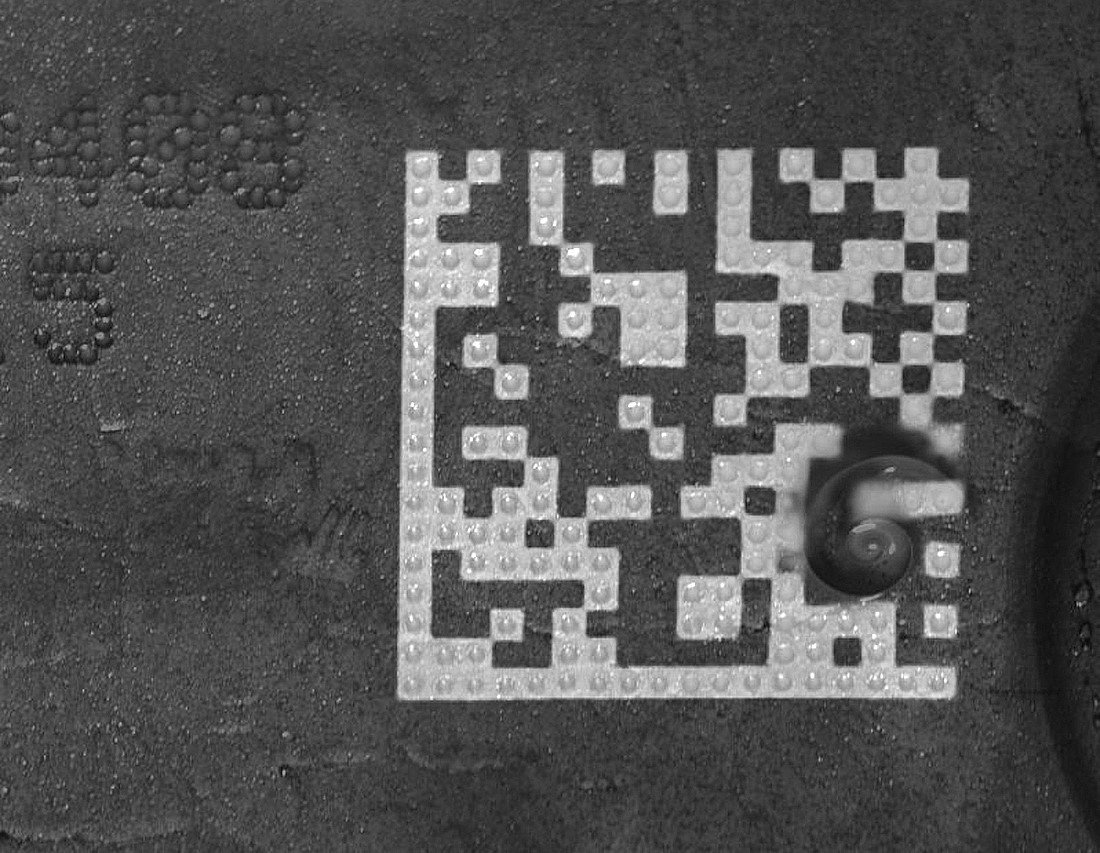

Contamination, poor lighting, and damaged codes cause problems for conventional scanners. When codes are not read, data gaps, rejects, and incomplete traceability result, jeopardizing quality and compliance.

Original vs. Vision AI Code Reader

Complete traceability in logistics and production with our Vision AI Code Reader

Code reconstruction even with contamination or partial obstruction

Read multiple codes simultaneously with a single camera

Scaling from single camera to dozens of cameras

Read rate close to 100% even with contamination and damage

Outperforms similar systems from well-known companies by orders of magnitude

Why Vision AI Code Reader?

The COMI Vision AI Code Reader sets new standards in traceability of products and components. Thanks to state-of-the-art AI technology, even damaged and heavily contaminated codes of any application type on all common materials can be reliably read.

In long-term tests with our industrial partners, we were able to achieve a read rate of 99.97% under the most difficult conditions – the top model from the market leader only achieved up to 70% here.

This precision is made possible by a combination of various vision models and our specially developed code library. Thanks to AI text recognition, the Code Reader can optionally also read machine and handwritten text.

Frequently Asked Questions

What you need to know about the Vision AI Code Reader.

The Vision AI Code Reader is an AI-powered solution for robust capture and automated processing of codes (e.g., Data Matrix codes, QR codes, barcodes, GS1) in logistics, production, and everywhere else. Our system relies on AI models developed over years that can reliably read even difficult codes in any environment and on any material. This eliminates the need for additional lighting and cleaning steps that would be necessary for reading codes with conventional systems.

Our Vision AI Code Reader reads all common code formats such as Datamatrix Code (DMC), QR Code, Aztec Code, PDF417 Code, and barcodes like UPC, EAN, CODE39, CODE128, etc. The codes can be printed, lasered, cast, engraved, or needle-punched, and applied to metal, plastic, wood, ceramic, glass, and other materials. With each read, our system can simultaneously read all codes in the field of view at once.

The COMI Vision AI Code Reader works similarly to other code readers at first: it is set up at the target location, e.g., in a production facility, and captures images there. But then our intelligent algorithms and AI models eliminate external interferences such as lighting, contamination, or damage and make even difficult codes readable again. The read codes, additional information, and if needed the entire photo are then forwarded to the configured target systems.

The Vision AI Code Reader offers a significantly improved read rate for heavily contaminated or partially damaged codes, e.g., due to scratches, lubricants, or shavings. In long-term tests with our industrial partners, we were able to achieve a read rate of 99.97% in difficult environments (light effects, lubricants and coolants, metal shavings, vibration) – the top system from the market leader achieved only up to 70% read rate in this test. Setup is simple and largely automated. The system is highly scalable from a single camera to dozens or hundreds of cameras in large industrial facilities.

Yes, connection to existing production control or warehouse systems is a standard component of the product. Common industry standards such as OPC-UA and modern formats like JSON-RPC are supported. We can also implement additional interfaces on a customer-specific basis at any time.

The system requires a camera (from a simple webcam to an industrial camera) and a PC or edge device for image processing. It runs locally on your premises – at workstations, on production lines, in warehouses, or in data centers. Alternatively, processing can also be handled via the COMI AI Cloud.

Let's enable AI together!

Do you have questions or would you like to learn more about the Vision AI Code Reader?

When you click "Schedule via HubSpot", data will be transmitted to HubSpot.

By submitting your data, you agree to the processing. For more information, see our Privacy Policy.