Vision AI Object Localization

Precise object detection and placement for automated processes

We enable AI for your robots

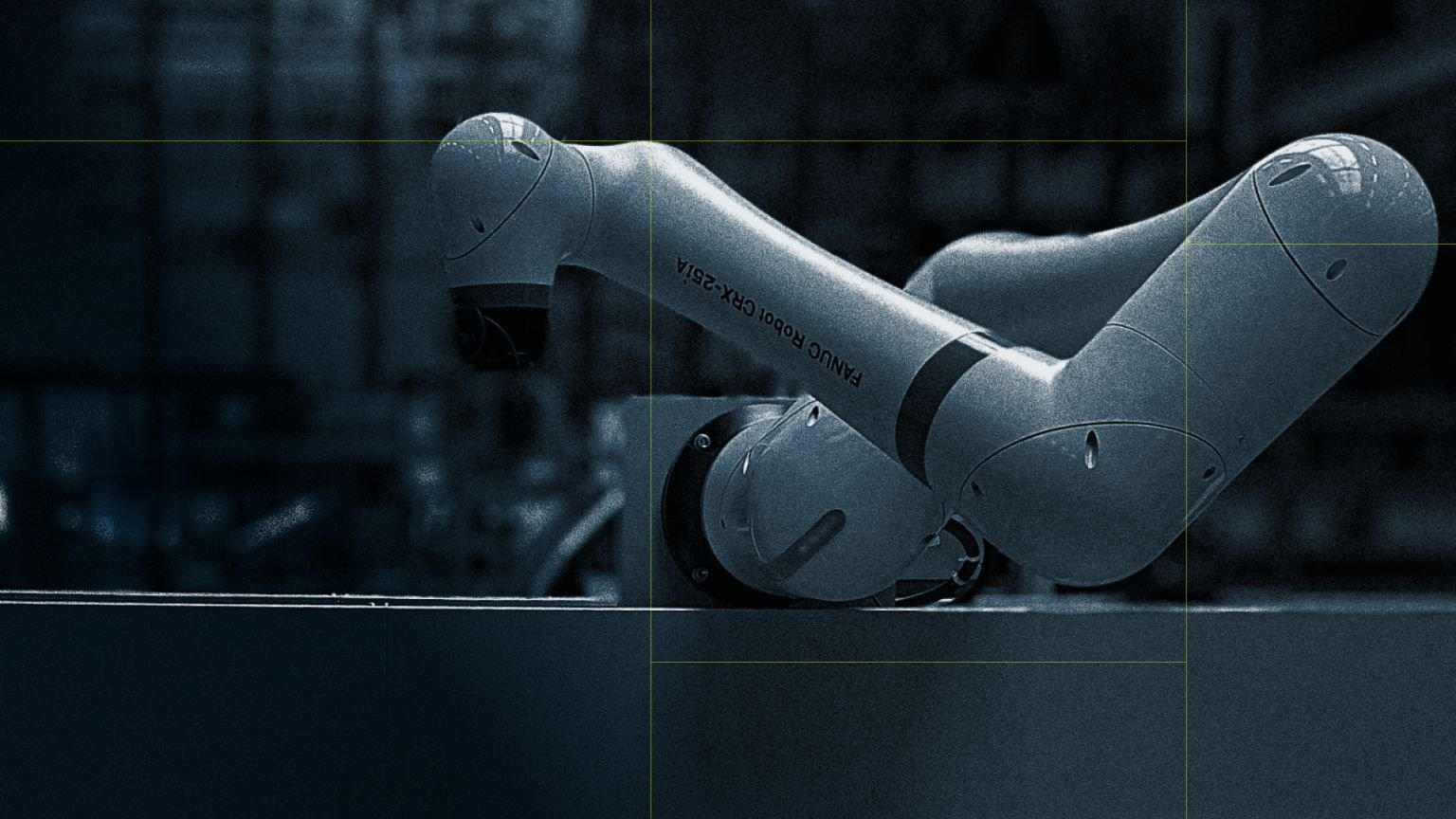

Precise object detection and placement using AI-controlled gripping robots for automated processes and autonomous systems.

In automated manufacturing, many robot systems are inflexible because they require exact placement positions. This increases the reject rate and limits production. Additionally, conventional systems do not detect incorrectly placed components, leading to collisions and expensive damage. Gripping is often imprecise when parts are positioned unexpectedly. Add to this the high setup effort, as each new component must be manually taught.

With our Vision AI Object Localization, we solve these problems through intelligent object detection that works flexibly and in real-time and can control any robot and gripping system.

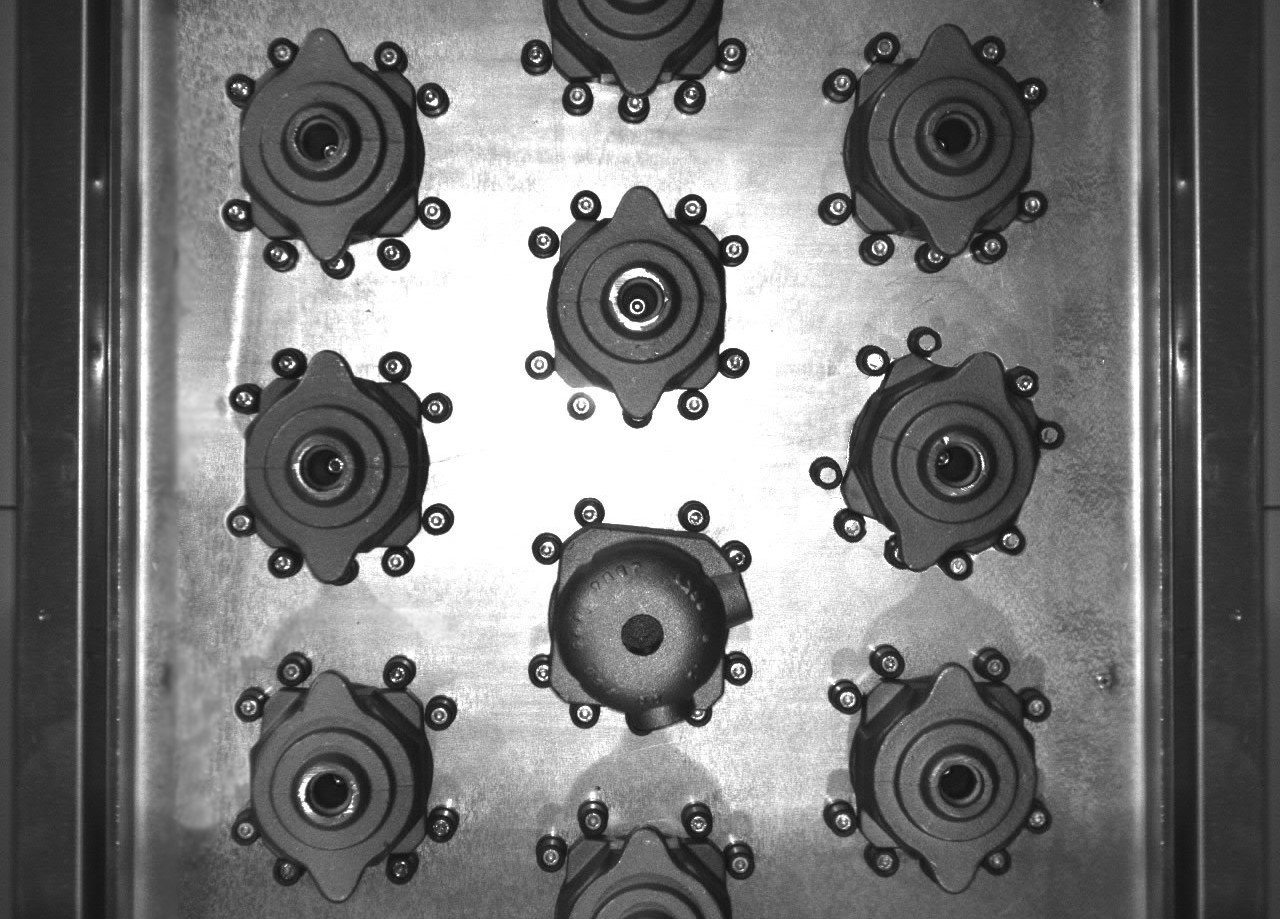

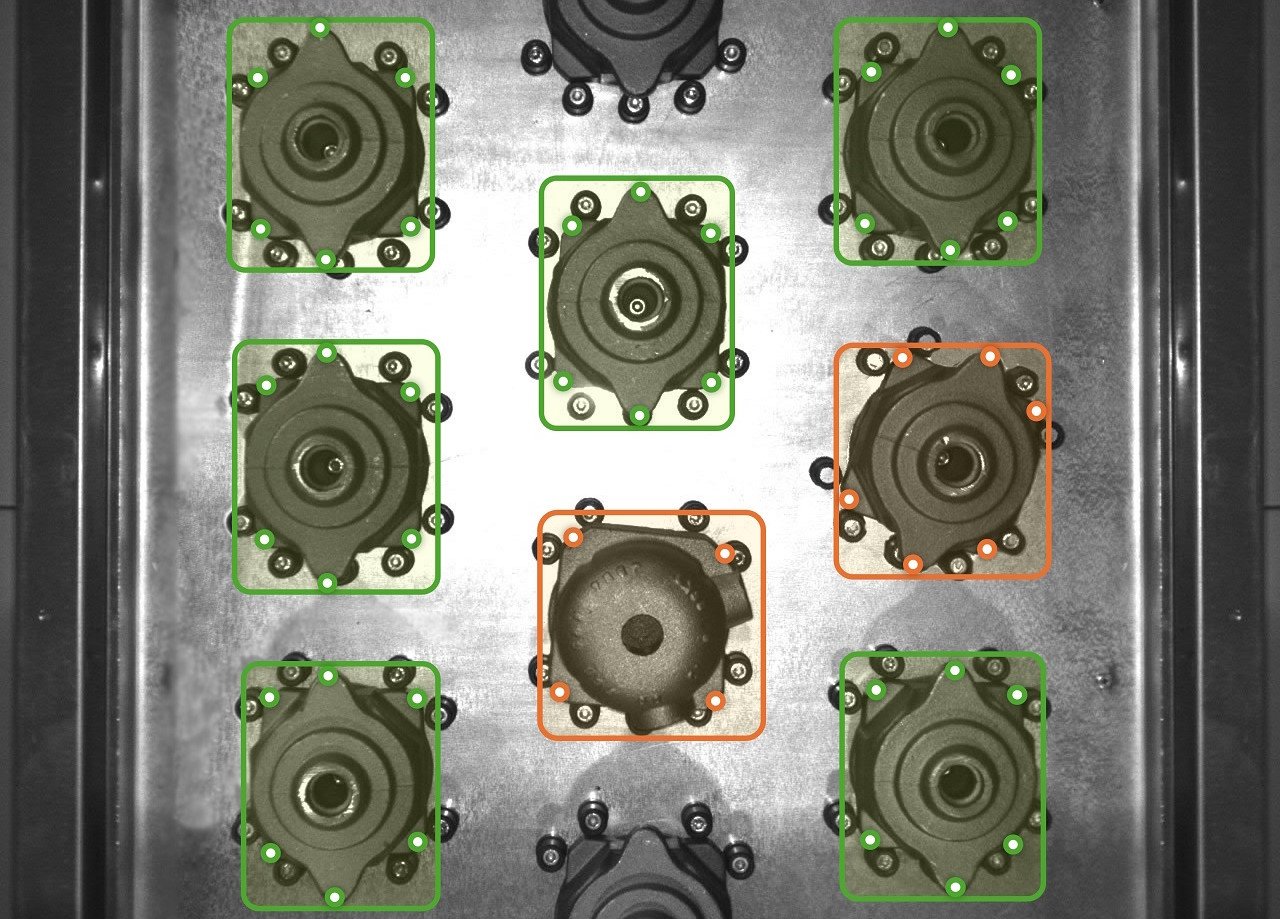

Original vs. Vision AI Object Localization

Intelligent Object Detection

Flexible gripping processes without complex programming.

Precise detection of objects in real scenes

Robust gripping from chaotic containers (bin picking)

Handling different object types and materials

Seamless integration with all major robot manufacturers

Frequently Asked Questions

What you need to know about Vision AI Object Localization.

Vision AI Object Localization is an AI-powered solution for precise detection and position determination of objects for automated gripping and placement processes.

Our solution is compatible with all major robot manufacturers such as KUKA, ABB, Fanuc, Universal Robots and many more.

With Bin Picking, the system recognizes objects in chaotically filled containers three-dimensionally and calculates optimal gripping points for the robot.

No, thanks to AI-based object recognition, no manual programming is required for new components. The system learns new objects quickly and flexibly.

The system requires a 2D or 3D camera and an industrial PC or edge device for image processing. It runs locally on your premises – directly at the robot cell, on the production floor, or in the data center. Integration with all major robot manufacturers is included as standard.

Let's enable AI together!

Learn more about Vision AI Object Localization for your automation.

When you click "Schedule via HubSpot", data will be transmitted to HubSpot.

By submitting your data, you agree to the processing. For more information, see our Privacy Policy.