We enable AI for your quality

Our Vision AI Verifier automatically detects defects and deviations in production processes – for maximum quality assurance and minimal reject rates.

Quality control in industry is often inefficient. Manual visual inspections are time-consuming, error-prone, and only capture samples, allowing defects to go undetected. Error causes such as tool wear or material defects are difficult to analyze because conventional systems only provide limited data. Additionally, many solutions only detect known defects while new defects remain undetected. Traditional testing methods are limited to individual measurement parameters, making precise fault diagnosis and efficient maintenance difficult.

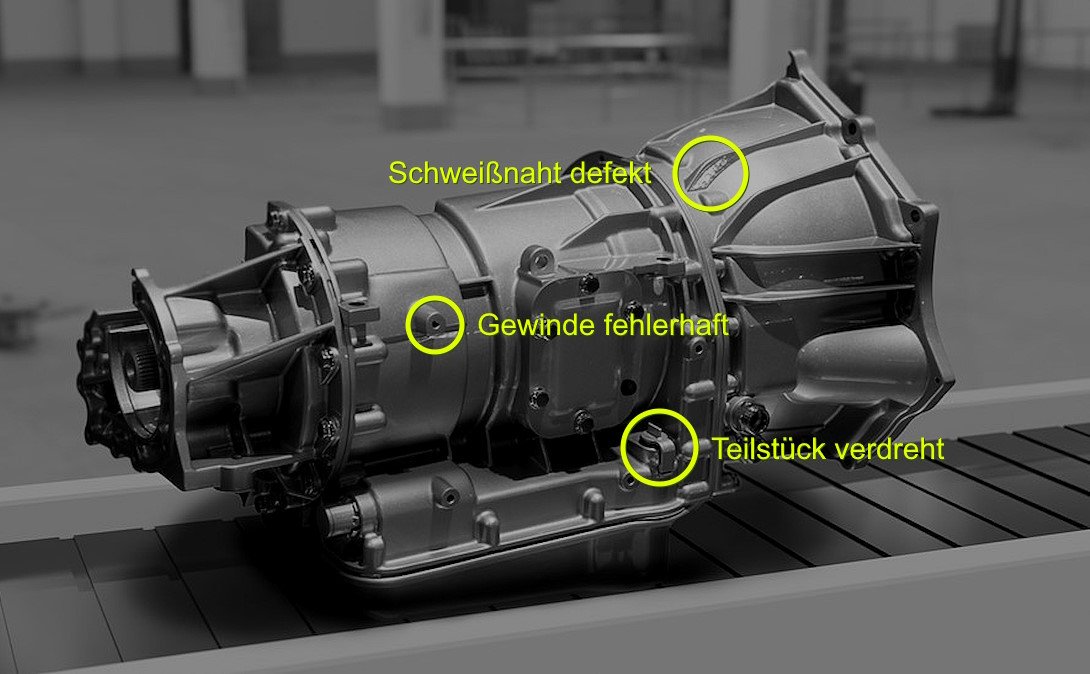

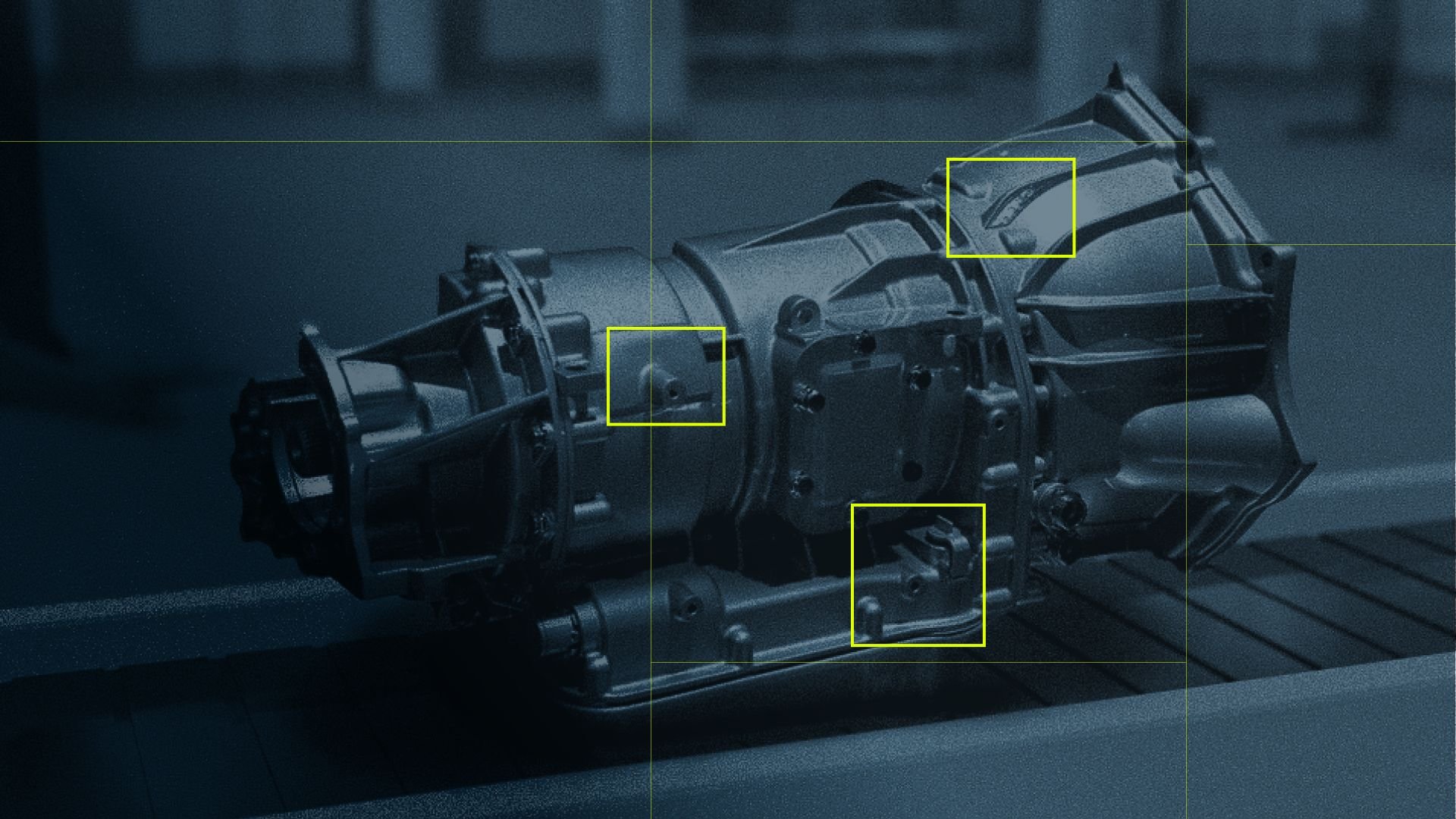

Our systems learn a deep understanding of your products' characteristics from just a few OK examples and can find and highlight any type of anomaly.

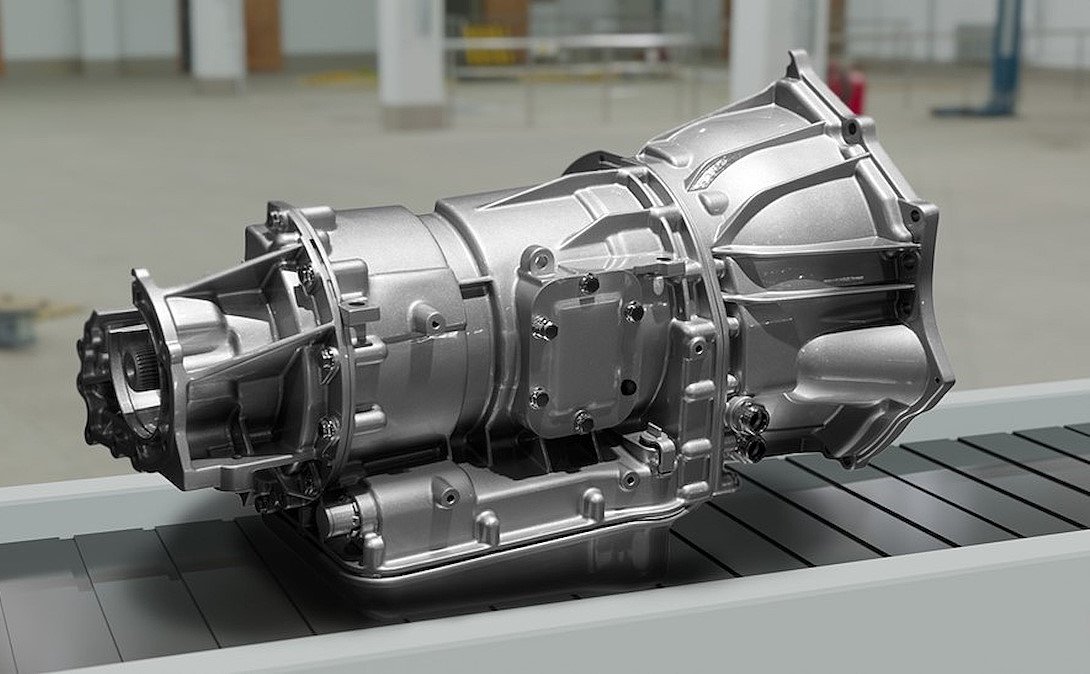

Original vs. Vision AI Verifier

Self-Learning Quality Control

Detection of unknown defects without extensive training.

Detection of unknown defects without prior training on specific error patterns

The system continuously improves through feedback from production

Immediate assessment of product quality directly on the production line

Seamless integration into existing production systems and MES

Frequently Asked Questions

What you need to know about the Vision AI Verifier.

The Vision AI Verifier is an AI-powered solution for automated detection and interpretation of unknown anomalies in production.

Using machine learning and computer vision, our system analyzes production processes in real-time, detects irregularities and reports potential defects early.

Early defect detection before rejects or production downtime occur. Self-learning algorithms that adapt to new defect patterns. Seamless integration into existing quality assurance and ERP systems.

The Vision AI Verifier is ideal for automotive suppliers, electronics manufacturing, mechanical engineering and all industries that need to ensure the highest quality standards.

The system requires one or more industrial cameras and an industrial PC or edge device for image processing. It runs locally on your premises – directly on the production line, in inspection areas, or in the data center. Alternatively, processing can also be handled via the COMI AI Cloud.

Let's enable AI together!

Learn more about the Vision AI Verifier for your quality control.

When you click "Schedule via HubSpot", data will be transmitted to HubSpot.

By submitting your data, you agree to the processing. For more information, see our Privacy Policy.